Automating your distribution

The rise of e-commerce is making it harder than ever to keep up with demand. Most packaging operations are typically done by crews because of the need for several people. They're labor-intensive and come with heavy labor costs. Keeping up with demand requires more than just a few workers. It requires automating your distribution and packaging operations to sufficiently fulfill online orders.

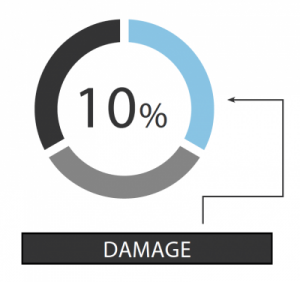

Damage is presenting a major issue for transit and secondary packaging. Consider this; 1 in 10 boxes experience damage during shipping. That number effects your company if you're shipping low or high quantities of products. While the e-commerce continues to grow, so do online reviews. Customers are able to voice their opinions on damaged goods, and products they must return. Those online reviews can single-handedly bring down a company, and it starts with your packaging. Damage prevention starts with the right evaluation of your process, followed by the proper automation to reduce damage. Packaging equipment can improve your process by creating a standard operation every time. No more mistakes from workers because the equipment will handle the majority of the work.

Damage is presenting a major issue for transit and secondary packaging. Consider this; 1 in 10 boxes experience damage during shipping. That number effects your company if you're shipping low or high quantities of products. While the e-commerce continues to grow, so do online reviews. Customers are able to voice their opinions on damaged goods, and products they must return. Those online reviews can single-handedly bring down a company, and it starts with your packaging. Damage prevention starts with the right evaluation of your process, followed by the proper automation to reduce damage. Packaging equipment can improve your process by creating a standard operation every time. No more mistakes from workers because the equipment will handle the majority of the work.

Automating your packaging operation

Is your warehouse fit for equipment and workers? If not, it may be time to re-think your warehouse layout and design. You'll increase your utilization of floor space and overhead volume by automating your logistics. Just think of all the space that those racks and pallet stacks require. Robotic forklifts use much less space, allowing you to shrink the size between racks. Freeing up more warehouse space also helps install packaging equipment, and that's where automating your line improves your process.

Machines can work long hours, as well as at night and on weekends, providing an overall increase in productivity. A cost comparison of skilled workers versus an automated system is the best analysis to determine if increased productivity can offset any human staff-related costs.

Automating your packaging line benefits your entire operation.

Automating your packaging line benefits your entire operation.It goes without saying that the key to successful warehouse operations is smooth, efficient product flow. But when you relay on employees to package your product, you leave yourself open to inefficiencies in your process, human error and mistake, inconsistent quality, ever-increasing labor costs and other operational difficulties that can easily be solved by moving to an automated system.

Put a stop to:

- Inefficiencies in your process

- Human error and mistake

- Inconsistent quality

- Ever-increasing labor costs

Packaging equipment and automation to keep up with e-commerce demand

The increase in demand of online orders and being able to deliver those products requires operations to look to the future. The future is robotics, packaging equipment, and automating packaging processes. Protective packaging is fundamental to the transporting of products from the factory to the end user. With e-commerce steadily climbing, that end user could be a single customer or an entire company. Make sure you keep up with those demands by keeping up your production. Read about the IPS Full Integration Difference below.