Everyone is looking for ways to reduce labor costs. Something that is often over looked is the use of packaging equipment to cut those costs. With an investment in packaging equipment, the initial investment may seem like a hit to your business. While this is true, it's also true that many pieces of packaging equipment achieve a positive ROI in less than a year. With case sealing equipment, your output can increase up to 600%, while also achieving dramatic savings in labor costs. How dramatic? Let's talk about saving $100,000 in annual labor costs due.

Packaging Problem:

An IPS customer’s business had just doubled. They were still manually erecting, packing and labeling boxes like they had done for many years.

Packaging Solution: Case Sealing Equipment

A free on site-consultation with an IPS Sales rep and IPS product manager generated an on-site demonstration that changed everything.

A free on site-consultation with an IPS Sales rep and IPS product manager generated an on-site demonstration that changed everything.

Our customer had skepticism over IPS’ ability to automate a process that was done by hand for years. That skepticism quickly changed to delight with the installation of three case sealers, each fitted with a two line dot-matrix case coder.

Wait a two line what now? Case sealing equipment is able to put the code on the boxes themselves. This new inkjet process had eliminated the need for employees to manually apply the labels. Hand applied labels were now a thing of the past.

Boxes no longer had to be pre-made before filling and were sealed automatically. Think of the convenience, think of the savings.

Their confidence in IPS’ quality service and products grew because we produced results that worked. This customer also reviewed other areas of their production process. That resulted in the purchase of a new semi-automatic pallet wrapper that replaced the old hand-wrapping process.

Benefits the customer is now enjoying:

• Manual processes replaced with automation. Saving money and improving efficiency.

• More efficient and safer pallet wrapping process.

• Space saving, area dedicated to making boxes is no longer required.

• 30% reduction in tape cost.

• 75% reduction in stretch film cost.

• Hand applied labels completely eliminated, replaced with ink jet printing.

• The 4 members of the 7 persons process has been redirected to more productive positions in the plant.

$100,000 savings for only a $26,000 investment upfront.

Oh yeah, those are annual savings.

You do the math, we think you'll see it's clearly worth the initial investment.

A good rule of thumb...

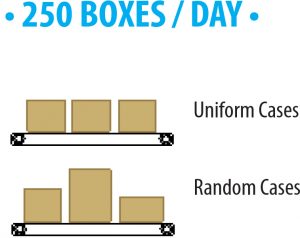

If you're packaging production reaches upwards of 250 boxes a day, you NEED to be automating your case sealing and erecting process.

Wondering just how popular it is amongst other facilities? Consider that 40% of the tape market is actually machine grade tape. So, nearly half of people who are purchasing case sealing materials are using machines. Material and labor savings, alone, can justify the initial cost of a machine in about a year.

LET US KNOW HOW WE CAN HELP