Benefits of a packaging engineer

If it’s not done correctly, packaging can be an expensive, time consuming, and frustrating process. It's quickly becoming a profit and productivity drain. You can change that with the right process and materials. The way to tie it all together is working with a professionally trained packaging engineer. They look for cost-savings throughout your entire supply chain.

Cost saving ingenuity

Engineers look to cut costs in your packaging in ways you probably have missed. What may seem like a simple process of protecting a product, is actually very complicated. It's a three step process to make sure the design of your packaging is the right choice.

- Evaluation

- Implementation

- Validation

Everyone's goal is different and packaging engineers should be evaluating your process based on your specific goals. Maybe it's to increase your bottom line, or maybe it's to maximize your efficiency. Whatever your reason is, you're taking a good first step in getting a packaging engineer involved. They'll look into your current workflow to find any problems that you may have. This usually happens with an on site review and complete documentation of problems and fixes. Here is where they'll find fixes based on your ROI guidelines.

Here's where engineers review numerous things that can and will effect your operation. Packaging compliance, warehouse space, and custom packaging all play an important part of fixing problems you may have. They'll then put into place the right answers as they fit, actual packaging solutions that will work. Some examples of areas they will look to improve; labor, storage, packaging design, automation process, and the total packaging management.

ROI, ROI, ROI. Analysis doesn't stop at the previous step. Engineers take steps to continually improve your packaging operations, that includes reviews. It's a good chance to get a glimpse of the project as a whole, and to go over any further steps that may help improve your process. They should be showing you the projected ROI and see if you have any follow up questions.

What to look for?

![]()

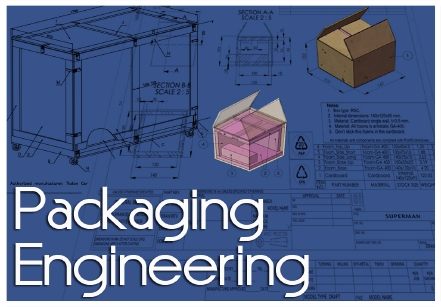

The right packaging engineer will be equipped with the latest packaging related software. We're talking SolidWorks, ArtiosCAD, and TOPS Pro. They'll offer several things that will help solve your most complex packaging issues. Engineers should be offering; consultation, custom design services, onsite placement, on-time project delivery and independent lab testing. The goal is to take this off your hands and into the professionals that will solve the problem for you.

Custom design

This is a big one as it'll have a direct effect on your products. Whether your shipping automotive parts or razors, the design of the packaging helps protect it against damage. Custom design corrugated, pallets, crates, and lumber. Keep those four in mind as they're most common for storing and shipping products. All in all, you want a packaging engineer that will work directly with your company with your needs for positive ROI in mind. You should view packaging as an integral part of your business model. Leaning on those engineers to make improvements will help get you where you need to be.