What is the difference in corrugation tests and does it even matter?

As packaging partners, we're used to getting a lot of questions about how to best manage their packaging needs without spending needless amounts of money. One frequently asked question is about the difference in corrugation tests. Mullen board and ECT board are both very strong and capable types of corrugated, but, sometimes, choosing one over the other may save you time, money, and potential product damage.

For many years, the Mullen burst test had been the industry standard for grading corrugated board for both secondary and tertiary packaging. However, as more recycled content has been utilized in the manufacture of corrugated board, it has been discovered that recycled board of the same basis weight did not always perform as well in the Mullen Burst test. But, these cases still had very good compression and damage resistance qualities.

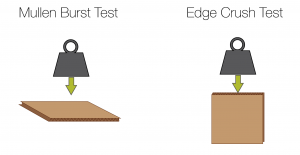

So, what, exactly, is the difference between the Mullen burst test and the Edge Crush Test (ECT) for boxes. Think about these two much like the ACT and SAT: the tests aim to tell customers how strong and durable a particular box is but in different ways. So, essentially, both the Mullen test and the ECT have the same objective, but their path of getting to that objective are not the same.

Mullen vs. ECT corrugation tests

The Mullen test measures bursting strength of the corrugated board. The Mullen test presses a rubber diaphragm bubble against the board in a defined area to measure the pounds of pressure per square inch (psi) ti takes to burst the board. Many customers like Mullen tested boxes for the protection of heavier contents because they are concerned about the linerboard bursting outward.

The Mullen test measures bursting strength of the corrugated board. The Mullen test presses a rubber diaphragm bubble against the board in a defined area to measure the pounds of pressure per square inch (psi) ti takes to burst the board. Many customers like Mullen tested boxes for the protection of heavier contents because they are concerned about the linerboard bursting outward.- The ECT Test measures the box board’s top-to-bottom compression strength (also known as stacking strength). This test looks at two areas of strength: box compression strength (BCT) and stacking strength. If a customer is concerned about the maximum weight a box can withstand, then ECT is your test. Today, this is the most common type of test used.

So if all you do is straight column stacks of product that do not bulge out against your container and are stored in controlled environments, then you would see very similar performance between Mullen and ECT board. But, most companies do not have these ideal conditions, handling and restacking boxes many times within their own distribution channels. The distribution hazards of shipping in a single parcel environment like UPS or Fedex are well known. They can wreak havoc on your packaging design, requiring different materials or a completely different protective packaging strategy.

In this case, you should see much better overall box performance from the Mullen board because of the configuration and natural strength of their longer fibers. You can also combine Mullen weight papers with traditional ECT papers to help offset costs and still create a better box. This is still relatively uncommon due to the special paper combinations and high volumes needed.

A good rule of thumb to remember is that Mullen boards contain more virgin material, meaning they have longer, interwoven fibers. ECT boards usually have a higher recycled content, which makes them less expensive, but the fibers are often worked more and the connective fibers are considerably shorter. Some paper mills will dye their higher recycled paper a darker tint to give it the appearance that there are more virgin fibers in the paper. Often the mills that produce the paper with shorter fibers use special processes to align the fibers in a vertical orientation to help with top to bottom compression strength.

In the end, it depends heavily on the application of your boxes. Sometimes ECT boxes is the right choice and will save you money, but there are many times that the ECT will cost you more in the long run with increased damage and customer dissatisfaction than buying the more expensive, virgin boards up front.

How we help make corrugation tests make sense

It sounds great to know what the Mullen vs. ECT boards mean. You can logically understand which provides the right protection based on your application, but when you're relying on your own understanding of an engineering concept, it may be time to bring in an expert. By working with a packaging engineer, you can get the right box for your needs, all within your budget.

For more information about Package Engineering or how an engineer can help you protect your products and enhance your shipping, check out The Logical Guide to Package Engineering.