Despite the rapidly changing packaging industry, many companies might be reluctant to change something that works, like shrink and stretch film gauge. There could be a perceived risk associated with downgauging for some. Chances are that if you are running the same gauge film you’ve run for the last five years, it’s worth evaluating possible alternatives.

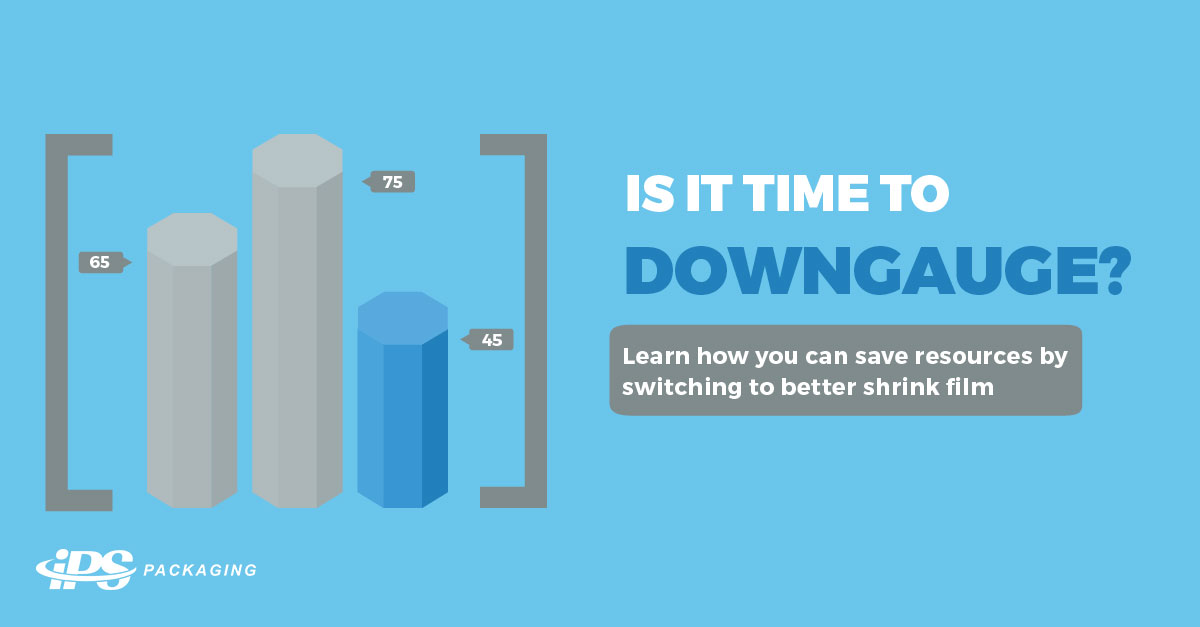

Many companies find that they can downgauge their film anywhere from 10% to 25% with some reducing materials by as much as 50%.

Let's show you how downgauging is another cost-saving measure that should be taking place right now in your packaging operation.

What to consider if you’re looking to downgauging

Application of the packaging

Downgauging depends heavily on the application. Because of this, it’s important to look at all stages of the packaging life cycle. What type of product is it? How about the distribution process? What is the shelf life? All of these things affect the film gauge. For example, a multi-pack application with voids will demand downgauged films that still deliver memory and puncture resistance. This is very different than the needs of a multi-pack of breakfast cereal, which has four flat supported sides.

Operation and Equipment

Operation and Equipment

Whether you have multiple lines running 24/7 or rely on hand operations with multiple change outs per day, your operations and equipment will impact your film gauge.

Distribution and Merchandising Concerns

Often savings can be found within your current film family: 60-gauge all-purpose film switching to 45-gauge shrink film has achieved significant savings at a consistently superior level of performance. High level of protection using 100-gauge film have found that a 75-gauge will achieve the performance they need.

Example: extreme temperatures during warehousing or transport, pre-boxed in retail-ready tray systems, stand alone on the shelf. Switching shrink products improves physical characteristics for your application, as well as lightens up your film.

Eye Appeal and Shelf Protection

Evaluating your products wrapped in actual film: do packaging mockups, wrapping your products in different gauges or shrink film products. It’s a great way to evaluate the feel, look, and shelf appeal of various shrink films, as well as the appropriate level of protection for your products. Downgauging sounds like your getting a lesser product, but that's not always true. In most cases, coming down on gauges will give you the same reliability in the film with less materials.

What to look for?

Superior film strength: Shrink and stretch film should provide the right amount of impact resistance and tear strength for product protection. Look out for tearing, ripping, and a shopworn appearance after handling. It's a good idea to test through the pack out and shipping when looking into lower gauges. The last thing you want is a film that is downgauged and it can't handle the shipping. Not all film strength is equal.

Superior film strength: Shrink and stretch film should provide the right amount of impact resistance and tear strength for product protection. Look out for tearing, ripping, and a shopworn appearance after handling. It's a good idea to test through the pack out and shipping when looking into lower gauges. The last thing you want is a film that is downgauged and it can't handle the shipping. Not all film strength is equal.

Clarity: Check out the superior haze and sparkling clarity. The film you're going down to may not have the same properties as the one you're using now. Shelf appeal can usually be viewed from the naked eye, a good distributor will be able to provide a summary of properties that compares to each film's clarity.

Crisp cleanup and fit: Check to see if the film wraps cleanly and evenly around the product. Is it a tight fit? Try pulling on the film once it's wrapped, does it seem solid? Some of the thinner films don't have the true balanced shrink characteristics in low gauges to create the cleanup and fit you need.

Conclusion

The shrink packaging community is encouraging downgauging as a cost savings measure. The use-age of smaller gauge shrink and stretch film uses less materials and ultimately costs less. If you do it incorrectly, however, it can be bad news for your operations. Film that rips, bursts and doesn't protect your products will end up costing you money in the long run. Still confused? Working with a knowledge distributor is the key to your success. You may not think the big savings are there, but small changes can produce big time results. They'll help walk you through the process to find out where you could be reducing materials and saving money.