Increased productivity

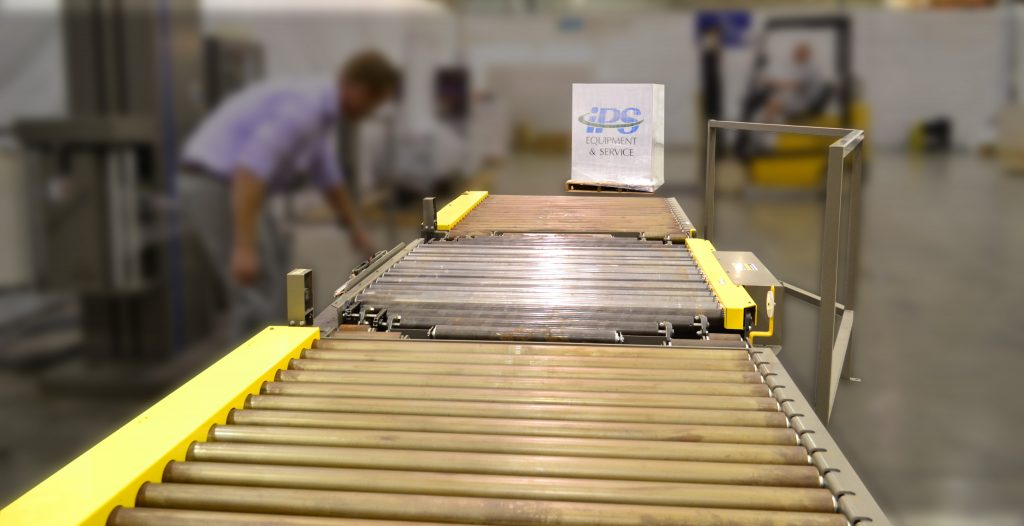

Packaging conveyors improve your packaging process and increase your productivity. How many times have we mentioned that "the key to successful warehouse operations is smooth, efficient product flow"? We say it time and time again, not to repeat it like it's going out of style, but to really drill home that message. Conveyor systems and integrated lines help keep your operations smooth and efficient. New technologies in packaging have advanced these systems to be more than just a simple movement of goods from point A to point B. These systems can now be used to move items along the line, weight loads, monitor loads, and more. When you automate your packaging line and rely less on people and more on machines, your productivity goes through the roof.

Advantages of using packaging conveyors in your process

Increased efficiency

Conveyor systems make the packaging process more efficient by automating certain aspects of the line. They're versatile, allowing certain sections to be running at a certain time. This helps reduce energy and the carbon footprint of your entire packaging operation. You'll also maintain a higher level of accuracy by automating your packaging line. Packaging conveyors are able to collect data while the operation is on going. Use conveyors to help with weighing product, sorting loads, and tracking loads along the line. Integrating packaging conveyor systems with equipment will put an end to inefficiencies in your process.

Flexibility

Most packaging conveyor systems are modular, allowing for mobile and flexible use along the packaging line. This lets you customize the system to fit your packaging operation. This is key, because we all know that no one operation is like the other. You need something that will fit the needs of your packaging process to really improve the productivity. Conveyors will help transport packaging materials and products in your warehouse as well as straight through the line. Don't think of them of just being a straight line anymore.

Quality control

Integrating conveyors and automated systems help control the quality of your packaging. They help orientate products to be packaged correctly on the line, instead of the time-consuming process of labor. Inconsistent quality is a major problem when it comes to packaging. 1 in 10 boxes shipped will be damage, and that really adds up. Creating stable loads, with the help of packaging conveyors, will let you recover up to as much as 50% of potentially lost products. Keeping your products and packaging in line help improve your quality, resulting in less returns and happier customers.

Better operator safety

Safety can be a very expensive part of the packaging process that is often overlooked. It costs US businesses over $15 billion a year to manage the costs of injuries resulting from falls. Slips and falls account for 15% of accidental deaths in warehouses, 25% of injury claims, and a whopping 95 million lost work days per year. Aisles and walkways that are unorganized and crowded can cause tripping hazards, especially if you’ve got lots of people moving around a packaging area to keep up with the demand. Packaging conveyors keep everything organized and out of the way, minimizing the risk of accidents in the warehouse.

More floor space

Take a look at your warehouse when you get a chance. Notice something? Space is at a premium when it comes warehousing facilities. With a conveyor system space is maximized, leaving more space for inventory. Packaging conveyors are more than just straight lines. They can get vertical and utilize roof space. Customized to fi any area of your warehouse, these systems allow for larger packaging workspaces. This ultimately leads to increased output.

Integrating conveyors into the packaging line

You've seen just how packaging conveyors can improve your process. Integrating these systems and automating your packaging line will improve your bottom line. With numerous advantages to using them, conveyors just make the packaging process easy. Add in a positive ROI and you can see that they just make sense. Every packaging operation is a different one, there's no one size fits all. When you take the time to look at your operation, you see that integrating packaging conveyors into your line will improve process.

Follow our Knowledge Base for the latest blogs on packaging supplies, equipment, case studies, and more ways to save money.

Follow us on LinkedIn, Twitter, and Facebook and click those share buttons below if this post helped you.