Packaging problems too terrifying to look at

We see a lot of scary things out there when it comes to packaging. Packaging problems so terrifying, you almost just have to look away. Whether it's issues with your packaging process, not using the right materials, or not investing in ways to make your operation more efficient; it's scary out there. We're here to help guide you down the haunted path of packaging problems so you can go from "trick" to "treat".

1. Hidden damage costs that go bump in the night

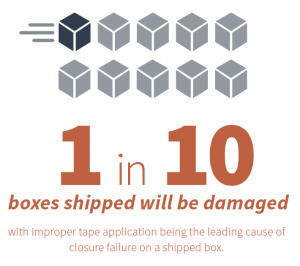

The total cost of packaging damages doesn't exactly jump out at you, they startle you indirectly. That's because, like most ghosts and goblins, they're hard to see. We're talking about concealed damages, labor costs, customer satisfaction, and safety issues. If you're still seeing damages to your packaging, you're still doing it wrong. Packaging damage effects everyone and everything. Packaging problems like not using the right void-fill, wasting packaging materials, boxing products incorrectly, and not tracking packaging damage will hurt your process. Visible damage issues are always seen, to both the customer and company. It's those hidden costs that will haunt your operation for years to come.

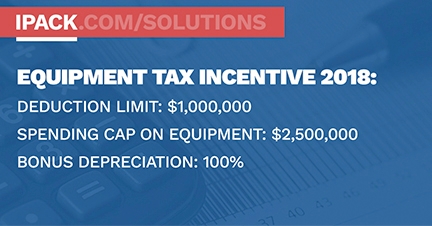

2. Not cashing in on 2018's equipment tax incentive

The equipment tax incentive increase for 2018 is up $500,000 this year. The incentive is now 1 million dollars for equipment this year. Not taking advantage of those tax write-offs is too spooky to comprehend. Unless you're scared straight of packaging equipment, you're losing out on valuable tax breaks and a more efficient process. Sticking with manual packaging costs your company money, while equipment and automation can improve your bottom line. We've got more on the benefits packaging equipment here.

3. Horrifying ways of using stretch wrap incorrectly

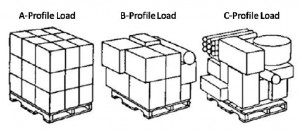

Stretch wrap; one of the most common materials when it comes to shipping. Used to wrap items on a pallet and secure them during shipping and storage, it seems pretty straight forward. Here's where things can get real chilling; not knowing how to use stretch wrap correctly. This scare starts with what type of load you're wrapping. There's 3 types: A loads, B loads, and C loads, each more frightening than the last. You can learn more in our complete Stretch Wrap Packaging Guide. There's also the neck-down effect, (sounds scarier than it is). When securing items, there's a tendency for the film to narrow. This effect is called neck-down and it reduces the coverage that stretch film provides. Don't be afraid to learn the do's and don'ts when it comes to stretch wrap.

4. Being afraid of working with packaging engineers

The spookiest part of packaging is the fact that it can be time consuming and expensive if it's not done right. It's also something that most companies aren't thinking about. You don't know what you don't know right? Working with packaging engineers is a beneficial process that will lead to cost-saving options. All products aren't created equally, and most of them deserve customized solutions. Problems with your packaging can seem helpless and down right eerie. Being overwhelmed with costly damage and loss of profits can cause your head to spin like the girl in The Exorcist. Want to see for yourself? Watch our non-spooky video showcasing our new engineering sample table. It's not scary, I promise.

5. Not using packaging to improve brand image

We talk a lot about packaging here, and rightfully so. We've been in the industry for over 40 years now and it's what we know. To some, packaging can be something you don't think about. "It's just a box protecting a product". That couldn't be further than the truth. Have you ever though of #packaging as a way to get your brand out in front of people? Think of the last time you personally purchased something from Amazon. What did that package look like? I bet you could draw it from memory right now. Everyone's seen the Amazon tape or the printed box when it arrives at their door. That's exactly what packaging can do for you. Think of printed packaging tape that can be used to market your company on boxes. Customized poly bags can include your company logo and information right on the bag. Boxes can always be catered to what you need, including graphics. These are all popular ways to use packaging to put your business in a positive light. See, not every packaging problem has to be scary.

More mysterious packaging problems we've solved:

- Case study: Pop-up box saves nearly 200K in labor

- Pallet redesign eliminates damages

- Case Study: Auto bagging system saves 65% in labor costs

- Tile wholesaler reduces damage by switching to foam-in-place system

Follow our Knowledge Base for the latest blogs on packaging supplies, equipment, case studies, and more ways to save money.

Follow us on LinkedIn, Twitter, and Facebook and click those share buttons below if this post helped you.