*Updated 1-22-18

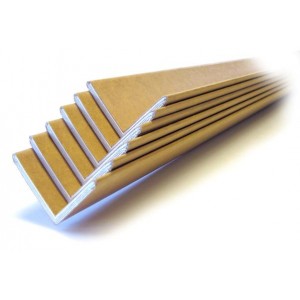

Angleboard, also known as cornerboard, is integral to proper pallet packaging.

Angleboard is an innovative solution to safeguard shipments both in and out of transit. When sized correctly, it works to protect the stretch film surrounding the load, packaging of the product and the product itself. Furthermore, it not only protects the corners of packaged product, but also adds structural strength to the pallet for stacking purposes.

Angleboard basics

Many companies in fact use the wrong size of angleboard. Using boards that are too large yields unnecessary waste while too small does not provide the proper level of protection for the product being packaged.

The proper use of correctly sized corner board along with corrugated pads between pallets gives the stack the structural integrity required to support itself without risking product damage through either compression or tilting.

The proper use of correctly sized corner board along with corrugated pads between pallets gives the stack the structural integrity required to support itself without risking product damage through either compression or tilting.- The leg length, or width of the piece, determines the amount of corner stress applied to the load.

- Shorter leg length coupled with greater thickness actually reduces the stress.

When properly adorned with corner board protecting each of the package’s corners, a strong base keeping the stretch film in place and providing the unit with an even amount of tension across the load.

Learn more: Angleboard SB Series: A new cost-effective cornerboard product

Increasing protection throughout distribution

For certain packaging applications the leg length may be more important to corner protection, but more often than not, the thickness of the board is going hold added value.

- The board thickness provides protection against bumping and/or rough handling throughout the distribution flow.

- The corner boards help hold product stored together on a pallet tightly, thus minimizing load shifting.

The rigors of shipping cannot always be anticipated; proper packaging of product must be considered in order to meet any accidents that may occur during the shipping process. This concept holds true in storage as well, as product is moved around the warehouse for inventory purposes or as the overall storage system changes over time.

Key to stacking strength

Counter intuitively, the leg length is often too long for most packaging needs.

- The true strength of the angle board comes from its thickness.

The thickness of the corner board provides more than just protection for the corners of the product from being damaged during shipping but also provides the required strength for stacking pallets.

- Stacking pallets allows for increased use of warehouse and shipping space by allowing the same amount of product to make less of a footprint, essentially doubling storage space.

Improperly stacked material can raise expenses if it results in damages to the product. The proper use of correctly sized corner board along with corrugated pads between pallets gives the stack the structural integrity required to support itself without risking product damage through either compression or tilting.

The proper use of corner board ultimately saves company expenses through product protection in shipping and storage. Proper selection of the corner board size can reduce costs and waste. It saves further by reducing shipping and storage space required. Corner board is reusable, and at the end of its natural life recyclable to fit with eco friendly business models. A knowledge of corner board’s uses and applications is essential to any production based business.

*Editors note. This post was originally published on October 18, 2013 and has been updated with the most up to date content.

See also: