Flutes: A corrugated symphony of structure

Architects have known for thousands of years that an arch with the proper curve is the strongest way to span a given space. The inventors of corrugated fiberboard applied this same principle to paper when they put arches in the corrugated medium. These arches are known as flutes and, when anchored to the linerboard with a starch-based adhesive, they resist bending and pressure from all directions.

When a piece of combined board is placed on its end, the arches form rigid columns, capable of supporting a great deal of weight. When pressure is applied to the side of the board, the space in between the flutes acts as a cushion to protect the container’s contents. The flutes also serve as an insulator, providing some product protection from sudden temperature changes. At the same time, the vertical linerboard provides more strength and protects the flutes from damage.

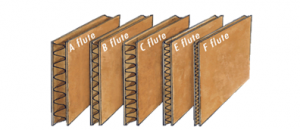

Flutes come in several standard shapes or flute profiles (A, B, C, E, and F). A flute was the first to be developed and is the largest common flute profile. B flute was next and is much smaller. C flute followed and is between A and B in size. E flute is smaller than B and F flute is smaller yet.

A flute: the original flute profile for corrugated board. It has about 33 flutes per foot.

A flute: the original flute profile for corrugated board. It has about 33 flutes per foot.- B flute: developed originally for canned goods. It has about 47 flutes per foot.

- C flute: developed as an all purpose flute and has about 39 flutes per foot.

- E flute: the next successful flute profile and has about 90 flutes per foot.

- F flute: developed for small folding carton-type boxes. It has about 125 flutes per foot.

In addition to these five most common profiles, new flute profiles (both larger and smaller than those listed here) are being created for more specialized boards. Generally, larger flute profiles deliver greater vertical compression strength and cushioning. Smaller flute profiles provide enhanced structural and graphics capabilities for primary (retail) packaging.

Different flute profiles can be combined in one piece of combined board. For instance, in a triple wall board, one layer of medium might be A-flute while the other two layers may be C-flute. Mixing flute profiles in this way allows designers to manipulate the compression strength, cushioning strength and total thickness of the combined board.