Shipping air bags for product protection

Dunnage air bags are the key to protecting truckloads during the shipping and receiving process. Dunnage is referred to as the material used to load and secure cargo during transportation. It can be used in numerous ways of transportation, including road, railway, ocean, or air. For our discussion, we'll keep it focused on truckloads, both full and LTL (less than truckload).

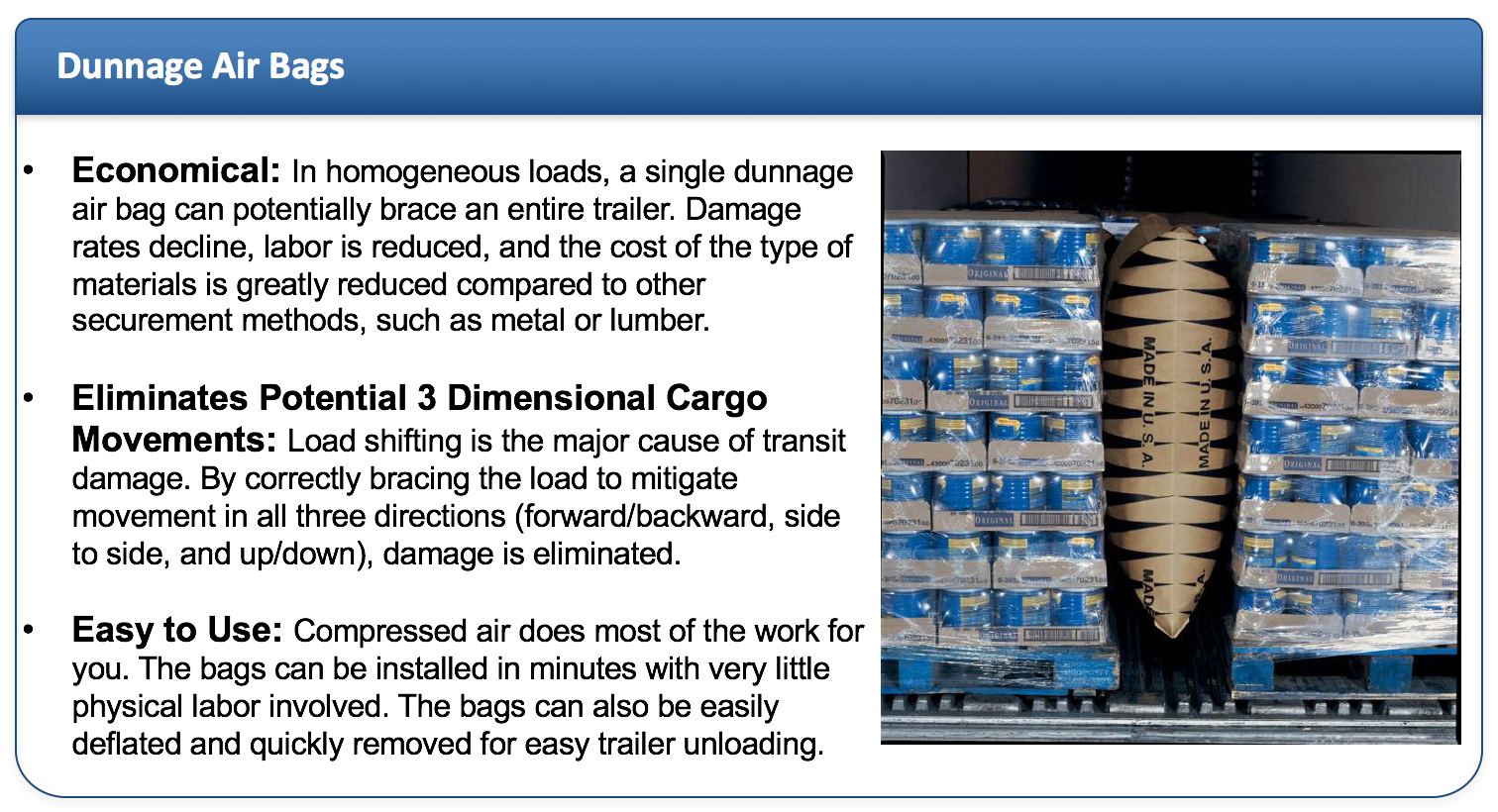

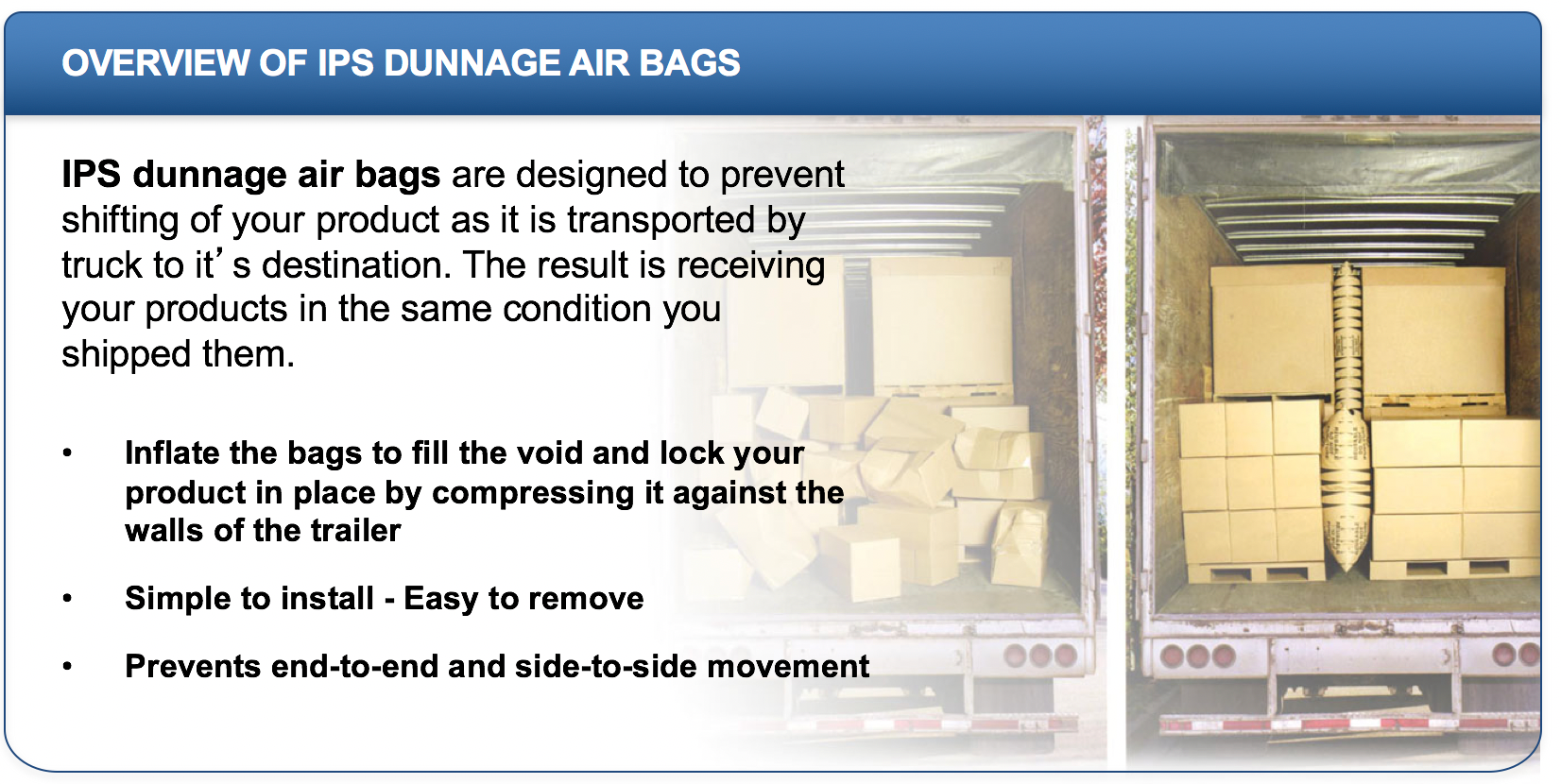

Simply put, dunnage air bags are air-filled pouches that fill the void between cargo items. They stabilize, secure, and protect pallets of products from experiencing damage during transportation. Not only do these dunnage bags limit movement from side to side, they also keep pallets from moving up and down.

Reducing the total cost of shipping

Many manufacturers worry about a product’s packaging and potential damage rates right up until the pallet leaves their stretch wrapping area. But, there is still a long way to go before it reaches its final destination, and most of that time is spent in the most dangerous aspect of its journey: transportation. No matter how it travels – by land, by sea, or by air – transportation is the part of the journey where significant damage can occur, if not properly managed.

When we talk about what it costs to ship products, we have to look at the total cost of shipping. This total cost includes many hidden costs associated with getting your products from your facility to where they're sold. Hidden costs include: concealed damage, labor costs, safety issues, and customer satisfaction. Visible damage is pretty easy to spot, you can see it right away. It's those concealed damages to your products you can see through the pallets, stretch film, and boxes. With dunnage air bags, you can reduce the amount of those hidden costs of shipping.

Watch the video below to see how dunnage air bags provide load stabilization to your truckloads of products.

Do I need dunnage air bags for my shipping process?

If you experience product damage during transportation, YES. Sometimes it's not that simple, so we'll lay out some simple ways to decide if you should be using dunnage bags.

- Do you ship full truckloads of product?

- Do you experience damage to your products during transit?

- Are you really maximizing the full amount of space in trailers?

Dunnage air bags are one of the most cost effective ways to fill the voids on trailers. These bags are air-inflated bladders made of different types of materials (including paper, plastics, and woven materials) that are used to fill the void spaces left when pallets are loaded into a trailer. By inflating them between pallets, shippers are able to lock the pallets in place by pressing them against the trailer walls and ensuring no movement.

Benefits of dunnage air bags

Some of the benefits of dunnage air bags include: reduction in materials, load and unload times, damage, and increases in efficiencies. Let's take a deep look at each of these to see why these shipping bags return positive ROI.

Reduction in materials: Can you use less stretch film to wrap your pallets while still getting the same or better product protection? Check this out. A distribution center was averaging 14 wraps per pallet. With the inclusion of air bags in their trailers, they were able to decrease the number of wraps to 8 per pallet, decreasing their material usage by nearly 43% per pallet. When you’re wrapping thousands of pallets a day that quickly adds up, potentially savings millions each year.

Reduction in load and unload times: Time is money, how many times have you heard that? The addition of air bags can help to reduce average unloading time by up to 66%. Not only are you saving time, you're saving money because you pay less for driver downtime and less fuel consumption as the truck is idling.

Reduction in damage claims: Freight damage happens all the time, whether its visible or not. It only takes an instant, a fast break, potholes, a fast turn, for damage to occur. Installing dunnage air bags in trailers to fill the voids left between pallets will help reduce damage claims by up to 80%.

Reduction in damage claims: Freight damage happens all the time, whether its visible or not. It only takes an instant, a fast break, potholes, a fast turn, for damage to occur. Installing dunnage air bags in trailers to fill the voids left between pallets will help reduce damage claims by up to 80%.

Increase in efficiencies: By using air bags to help secure loads, the need for the more traditional methods, such as the stair stacking technique, is eliminated. By rearranging the load style, shippers are able to increase the number of cases they ship out by up to 10% per truck load.

More dunnage air bag knowledge

So you've read through, and gained some knowledge on dunnage air bags. Glad to help out, but there's more to learn. If you're really interested interested in fixing your current product damage problems or want to get ahead of the curve, we're here to help. You can download our white paper on air bags below. It takes an in-depth look at dunnage bags, the process that makes them successful, and how they can help improve your process. Air bags make total logistical sense, you can download it for free below.

Inflate your brain with more knowledge:

- Choosing the right dunnage air bag

- Reducing the cost of shipping with dunnage airbags

- Case study: custom air bags for unique loads

- Autoflator: Dunnage air bag inflation device

- Dunnage Air bags for the poultry industry

- Dunnage Air bags overview

Follow our Knowledge Base for the latest blogs on packaging supplies, equipment, case studies, and more ways to save money.

Follow us on LinkedIn, Twitter, and Facebook and click those share buttons below if this post helped you.