A case sealer can save you thousands in material and labor costs

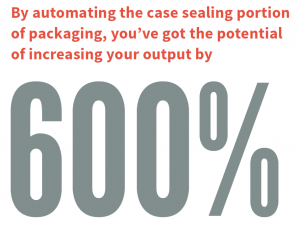

By moving from hand taping to machine sealing, you can see an increase in productivity and decrease in materials costs. Case sealers mean that your employees are spending 50% less time per box, saving thousands of hours per month, which in turn, depending on the number of boxes you’re processing each year, could equal nearly $1 million in labor savings alone.

Consider the following: someone hand sealing boxes will use more tape (and take far more time) than a machine. An automated sealer uses a single 1,500 yard roll of tape to yield an output of 3,176 boxes; by comparison, a person would utilize a 220 yard roll and yield only 110 boxes, equating to 6,352 yards of tape to achieve the same result as the machine.

And a 1,500 yard roll of tape will cost less per inch – an average of 30% less. It will also need to be replaced far less than a 220 yard roll, and you’ll have less waste per roll because a machine can be programmed to use more of the roll than a person might. Those savings alone could equate to thousands of dollars per year.

ACTUAL CUSTOMER SAVINGS:

- 30% less material used per case

- 100 million feet used per year

- Saving 30 million feet per year

- $0.005 cost per foot

- Total savings per tape in one year = $150,000

Sealing by hand results in inconsistently presented boxes, which, in turn, can make your business look unprofessional and can make your product look low quality. You need to have a consistent and presentable look for your products and a carton sealer will help you effectively achieve this, using the same amount of tape, in the same location, on each box.

Of course, it all depends on the number of boxes that you’re processing each day. The rule of thumb is that if you’re sealing more than 250 boxes a day, then a case sealer will provide a great ROI. In fact, most equipment pays for itself within the first 9 months that it’s on the floor; if you’re running huge quantities, you may see a positive ROI within the first 3 months!

Ask yourself these questions:

Ask yourself these questions:

- Are you interested in a solution that would reduce labor costs?

- Would speeding up 1st shift production rates allow you to reduce or eliminate overtime?

- Are you concerned about customer complaints or reports of damage?

If you answered yes to any of these questions, IPS Packaging has produced a free white paper on the benefits of using a case sealer in your facility. What harm is there in taking advantage of the offer to learn more about the automation of sealing? You might find yourself in the position to save thousands.